Thermodynamic simulation

Czero has extensive experience with thermodynamic simulation, including a full range of power cycles, heat pump cycles, and gas compression. Project examples include bottoming cycles (Rankine cycle), gas turbines (Brayton cycle), turbo chargers, and compressed air energy storage.

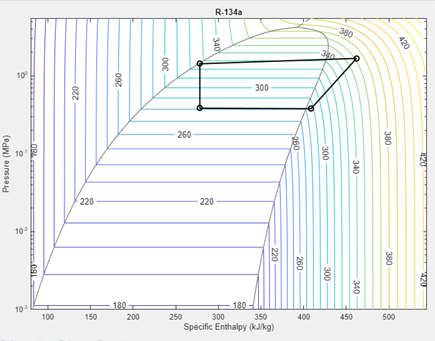

Thermodynamic system models are built to understand performance at different operating conditions, size individual components, determine the optimal working fluid for your application, and understand transient operation including start up and shutdown. Czero often uses MATLAB/Simulink/Simscape to build the system-level models, and uses NIST's REFPROP for thermodynamic and transport properties of fluids wherever possible to ensure accurate modeling of fluid states.

Heat pump modeling

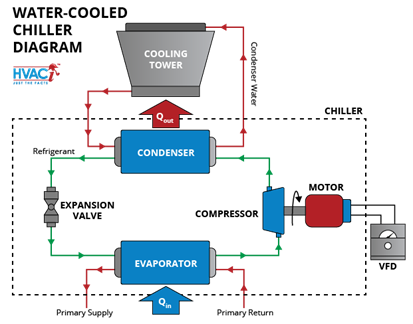

Czero has done numerous projects sizing refrigerant-based systems for heating and cooling needs. As more and more industries and products become electrified, traditional air conditioning and heating systems will need to be redesigned. For example, active cooling of batteries is often necessary and heating via a heat pump is needed to eliminate CO2 emissions and reduce loads on electrical systems. As another example, heat pumps can be used for transforming low-grade heat into industrial-grade heat higher temperatures which can be useful for hard-to-carbonize industrial sectors.

EV cooling and heating needs

Electric vehicles (EV’s) typically need sub-ambient cooling systems since Li-ion batteries cannot be operated at hot ambient conditions. In addition, heating the passenger cabin using direct resistive heating severely reduces the range of the EV. Since both the heating and cooling needs for EVs are substantially different from traditional fossil fuel operated vehicles, a full heating/cooling system re-design using refrigerant based cycles is needed. Starting the design process with dynamic models, Czero can help you size the system, choose appropriate components, and ensure the system will meet performance goals.

Modeling process for refrigerant-based systems

Before the system level model can be built, the individual components of a heat pump cycle (compressor, evaporator, condenser, and expansion valve) are modeled in detail using either supplier-provided performance data or a geometry-based method. Depending on the most appropriate modeling platform for the project, Czero will either calibrate Simscape pre-built components, or use our custom block sets for modeling the two-phase flow that occurs in evaporators and condensers. These block sets include specific correlations developed for evaporating and condensing refrigerant flows and have been validated via literature. These detailed models are often needed to provide the performance data of any components in the system if it is not available by other means. Once the individual components have been vetted, they are combined into a system model for performing sizing studies to determine the best combination of equipment to meet the project requirements.

Reach out to us, schedule a meeting, and let's find your custom solution.

We offer concept-to-prototype mechanical engineering R&D for developing systems and subsystems for cleantech innovations. Learn how we can help your team.