Hydraulic modeling for design and diagnostics

Czero has multiple engineers with over 30 years of experience and expertise in analyzing, designing, building, and testing high bandwidth hydraulic systems. Our expertise ranges from the design of single subcomponents such as digital valves with sub-millisecond switching times to entire subsea well control systems that have hundreds of valves and need to live in harsh environments.

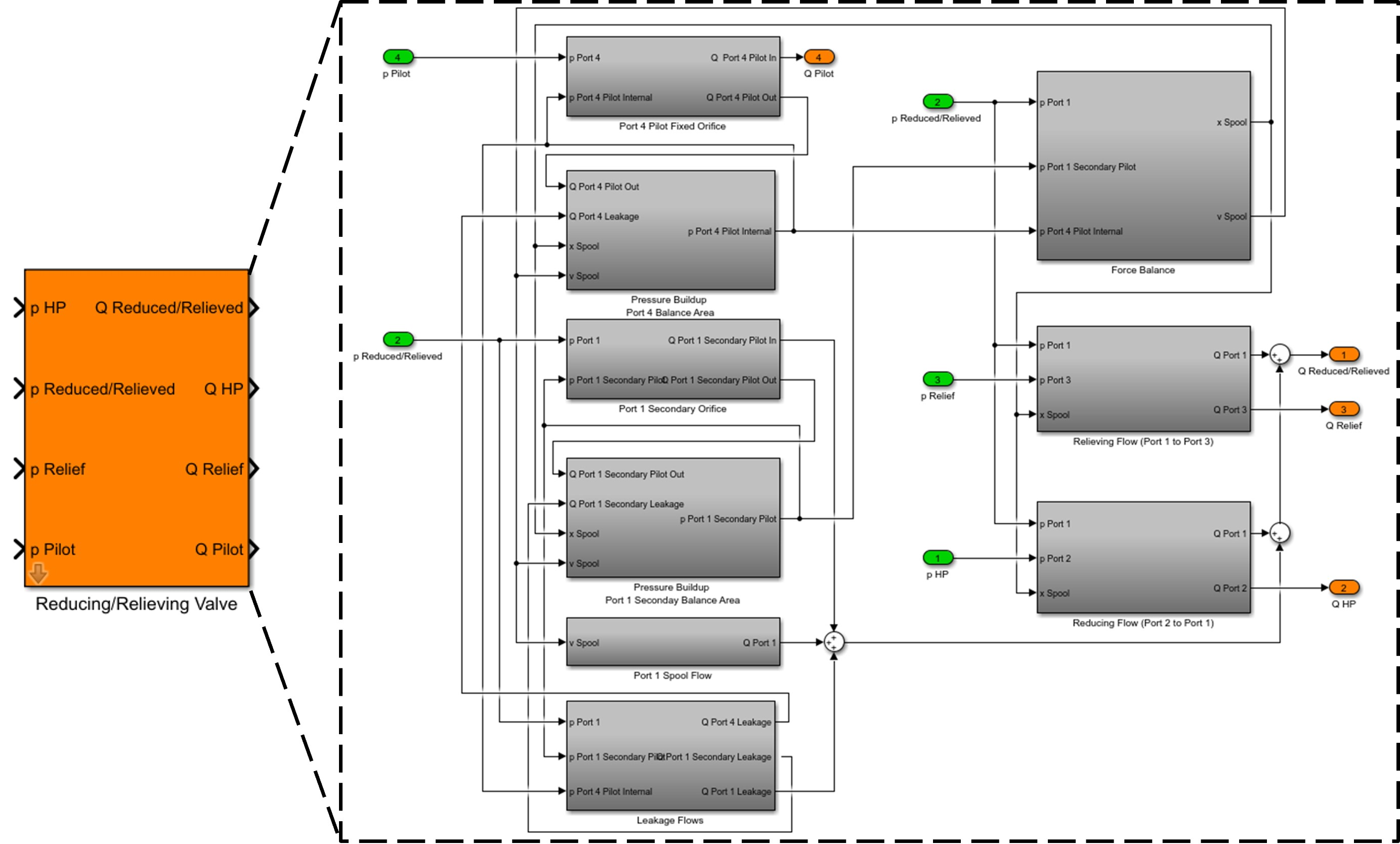

Every system and problem is unique and we work hard to bring the correct level of model and fidelity needed to fit the needs of our customer and the problem at hand. To facilitate this we have developed and extensive customized library of MATLAB/Simulink hydraulic blocks that allow us to quickly develop “right sized” models that gets you the best answers in the least amount of time.

While we are very comfortable taking on simple hydraulic problems such standard hydraulic circuits, our value lies in higher performance systems such as:

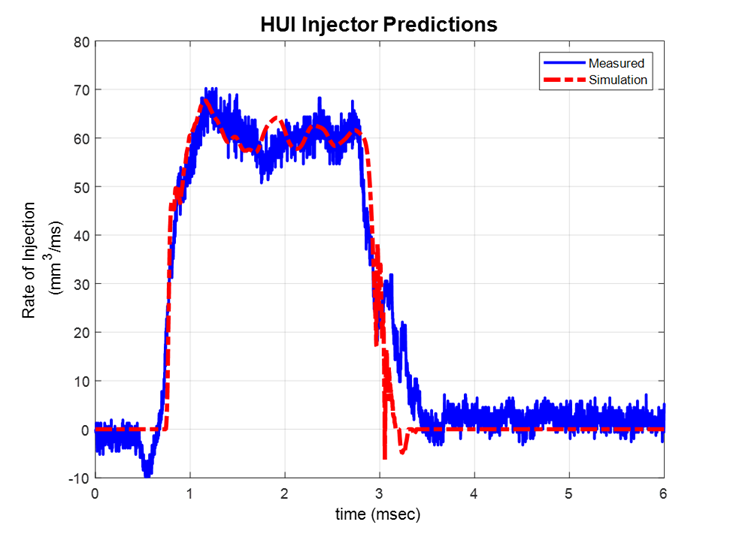

- Fuel injectors and injection systems

- Hydraulic valve actuation systems for internal combustion engine

- Digital pump controls

- Active and semi active ride control systems

- High bandwidth hydrostatic dynamometers

- Hydraulic driven compressor systems

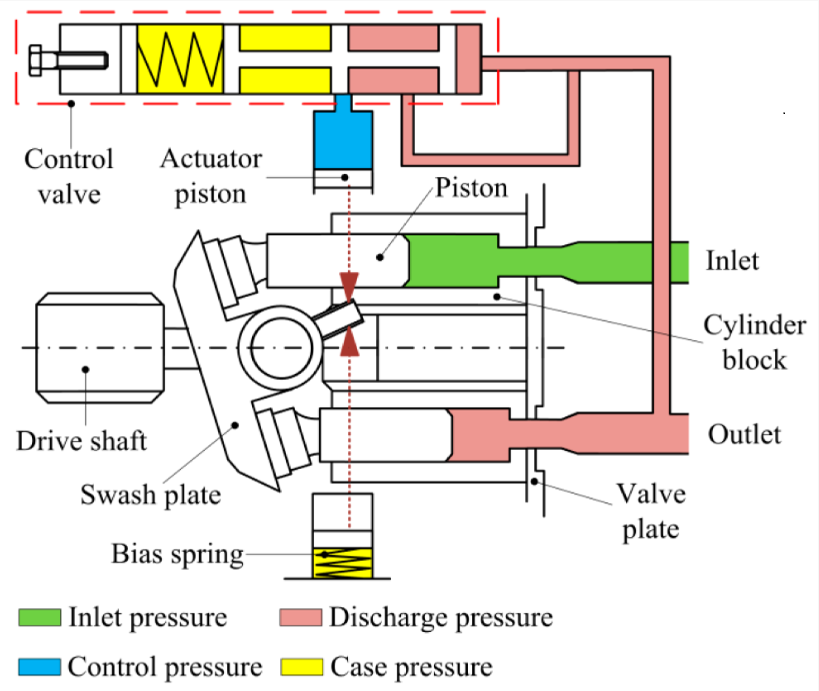

Physics-based modeling

Czero’s hydraulic blocksets are predominantly physics based and continuously validated with data giving customers high confidence in the simulation results. Czero engineers will work with the customer to make sure that only the appropriate physics are modeled. Physics that can be modeled with Czero’s hydraulic blocksets include:

- Wave dynamics

- Cavitation/air entrainment

- Heat transfer

- Flow forces

- Leakage

- Viscous damping

- Stiction

- Squeeze film and hydrodynamic film layers

Detailed models for all your needs

Our models can be used for designing new hydraulic systems, for diagnosing problems with existing systems and components, and for performance improvements and optimization. Detailed models can also be transitioned into real-time models for use with model-based controls, HIL systems or compiled for use with other software models or standalone operation.

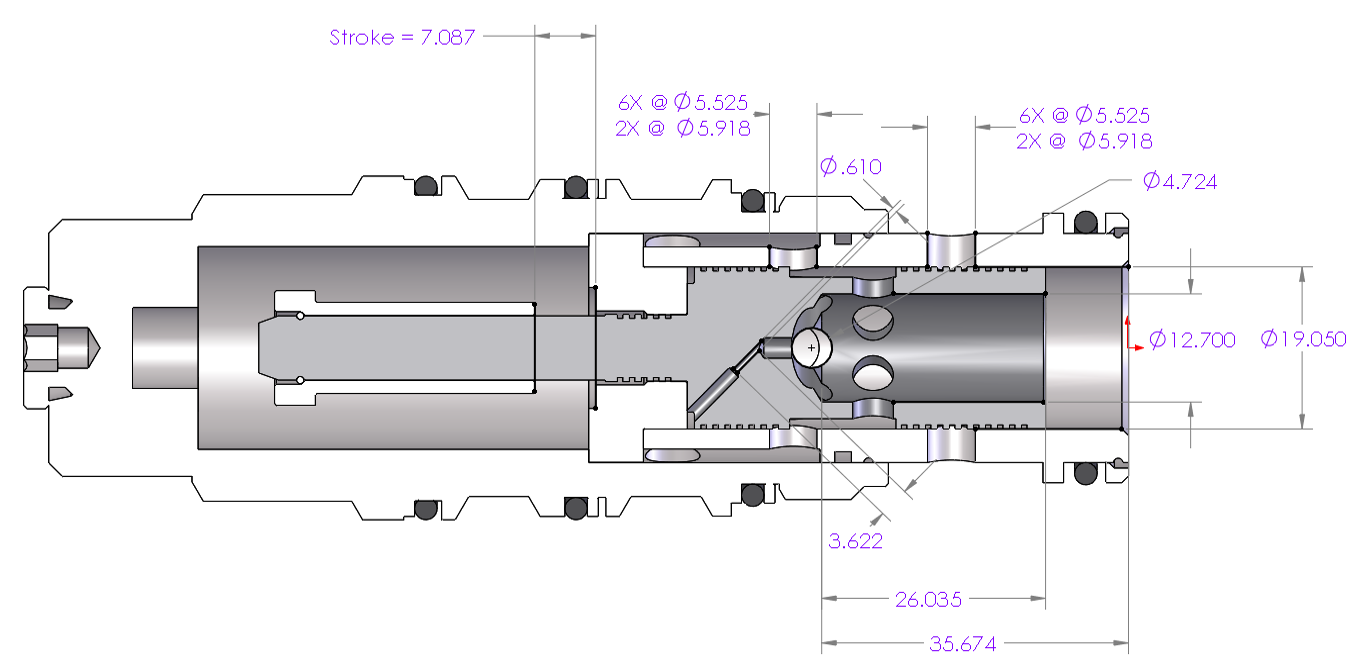

Example equipment

Hydraulic models can be full system models that have multiple components like pumps, valves, lines, accumulators, pump motors and tanks and typically have control systems as well. The models can also be very detailed stand-alone hydraulic models of, for example, a pump or fuel injector. A few of the detailed hydraulic components Czero has modeled are shown on this page.

Pumps:

- Piston

- Gear

- Vane

- Diaphragm

Valves

- Hydraulically actuated

- Magnetically actuated

- Digital on/off

- Proportional

- Servo

Injectors

- High pressure diesel

- Gasoline direct injection

- CNG

- LPG

- Hydrogen

- Port

- Fumigation

Miscellaneous

- Accumulators

- Line elements

- Orifices

- Hydrostatic transmissions

- Hydraulic hybrid systems

Reach out to us, schedule a meeting, and let's find your custom solution.

We offer concept-to-prototype mechanical engineering R&D for developing systems and subsystems for cleantech innovations. Learn how we can help your team.